Mercedes-Benz as Pioneer of the Digital Transformation: From

Car Manufacturer to Networked Mobility Service Provider

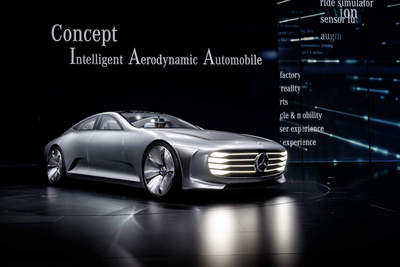

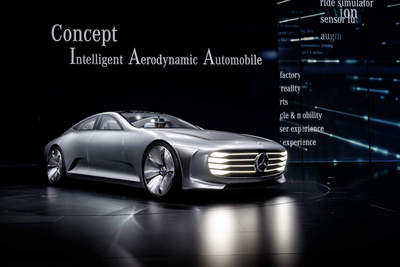

The Mercedes-Benz Concept IAA

(Intelligent Aerodynamic Automobile) is two cars in one

– an aerodynamic world record holder with a cd

figure of 0.19 and a four-door coupé with a

fascinating design. The study, which will be premiered

at the IAA in Frankfurt, automatically switches from

Design mode into Aerodynamic mode upwards of 80 km/h,

altering its form with a large number of active

aerodynamic measures.

|

FRANKFURT -- Sept. 15, 2015: The automotive industry is

changing fundamentally, things are speeding up. Alongside

“globalisation”, another megatrend is

“digitalisation” – also known in an economic context as

“Industry 4.0”. Mercedes-Benz is a pioneer in this development.

The inventor of the automobile is actively driving forward the transition

from automotive manufacturer to networked mobile mobility service. Dr.

Dieter Zetsche, Chairman of the Board of Management of Daimler AG and Head

of Mercedes Benz Cars, explained the strategy and the current status of

development on the eve of the 2015 Frankfurt International Motor Show

(IAA). Presenting the “Concept Intelligent Aerodynamic

Automobile”, known for short as “Concept IAA”, Zetsche

showed a concrete example of the fascinating opportunities offered by

digital product development.

Digitalisation has been a central strategic issue in all

areas of Mercedes-Benz for many years. Technical innovations like driveline

electrification and autonomous driving, in particular, would be unthinkable

without the digital transformation. The same applies to production, where

the brand with the three-pointed star likewise plays a leading role. In

parallel, the progress of digitalisation in the area of marketing &

sales means Mercedes-Benz is taking into account altered customer

expectations and the associated transformation in communication patterns

and behaviour.

“It’s about

nothing more and nothing less than the complete networking of the entire

value chain – from research and development, through production to

marketing and sales,” said Zetsche, speaking on the eve of the show.

“This digital transformation is in full swing at Mercedes-Benz. We

are transitioning from car manufacturer to networked mobility provider,

whereby the focus is always on the individual – as customer and

employee. This is how we will continue to develop the company and thereby

ensure our future competitiveness.”

Digital prototype – more speed, more

precision, more diversity

Digitalisation at Mercedes-Benz is particularly advanced in

the area of research and development. By way of comparison, computer

renderings with around one thousand elements were possible in the 1970s.

One decade later, this had risen to 25 times as many. Today, the figure

stands at up to 80 million elements and rising.

Digital prototyping accelerates the development of new

generations of cars – but more than that, it also raises their

quality and offers opportunities for increased diversity. The car of the

future is being simulated and optimised as a digital prototype from the

earliest stages of its development.

“With the aid of digital prototypes, we are also

improving the passive safety of our vehicles – faster, more precisely

and more efficiently than ever before,” said Prof. Dr. Thomas Weber,

Member of the Board of Management of Daimler AG responsible for Group

Research and Mercedes-Benz Cars Development. Another particularly

impressive example is aerodynamics. “The key term here is Big Data,

the evaluation of large quantities of data from a wide range of

sources,” continued Weber. “Before we let a new car anywhere

near our wind tunnel, it has already successfully passed a barrage of

digital tests as a complete data model.”

The opportunities and potential this unlocks for production

development are not difficult to imagine. One example is that current

Mercedes-Benz production cars are already aerodynamic world champions in

virtually all classes. The opportunities presented by digitalisation are

already being used to the maximum by the Formula 1 team. From add-on parts

such as aerodynamic features, through to new engine and drive components,

the route from computer data model to race track is often impressively

short and fast.

Production

– shorter innovation cycles and better

ergonomics

Production, too, is

becoming more flexible and efficient thanks to digitalisation. The aim is

intelligent production, notable for its transformability, resource

efficiency and better ergonomics for workers. Dr. Zetsche: “The more

diversity we have in the market, the more flexibility we need in

production. The key here, too, is digitalisation. Plants will become smart

factories, where equipment and components are seamlessly networked. And

what’s even more important – people and robots will work

harmoniously together in the smart factory of the

future.”

Robots are already

omnipresent in automotive production today – especially where the

work would be particularly strenuous or even ergonomically harmful for

people. Nowadays, an assembly step is generally completed either by workers

or by robots, the latter still being enclosed in protective cages for

safety reasons. This is set to change, with people and robots interacting

directly with one another in future.

Man and machine work

hand-in-hand

Combining the

cognitive superiority and flexibility of human beings with the power,

stamina and reliability of robots not only increases quality, but also

leads to significant improvements in productivity. And at the same time, it

offers a whole array of new possibilities when it comes to ergonomic and

age-appropriate work – also and particularly in respect of

demographic changes in society.

Markus

Schäfer, Board Member responsible for Mercedes-Benz Cars Production and

Supply Chain Management: “The intelligent cooperation of people and

robots plays a central role for us. To state it clearly, the use of new

types of robots is not a matter of ‘man or machine?’ We are

committed to an intelligent teamwork approach.”

Wilfried Porth, Member of the Board of Management of

Daimler AG responsible for Human Resources: “The experience,

creativity and flexibility of our colleagues cannot be replaced by robots

– now or in future. There will, however, be less seriously strenuous,

heavy work. This is what we see as the ideal division of labour between

people and robots.”

Production planning – increasing flexibility

and precision

Through digitalisation, production equipment and

installations can be designed to be highly flexible in future, enabling

construction, expansion and adaptation without major delays. This not only

improves the prerequisites for long-term planning, but also enables faster

response to short-term shifts in the market.

One example of this transformable production is the

so-called object-coupled assembly system, whereby mobile robot systems can

be used in production in a variety of different ways, without the need to

technically modify or stop the production line. The robots can dock onto

the respective bodyshell on the production line, carry out their work and

switch to the next vehicle while the line keeps moving. Daimler is also

using digitalisation in quality assurance, involving the cooperation of

entire installations. Smart factories, holistic automation and control

technology, company-wide standard modules and new, network-based working

models will enable detailed dialogue between individual plants in future.

This will see the global network of Daimler AG grow closer together and

lead to greater efficiency in production and sales.

This efficiency will also carry through to suppliers

– problems with a production system can be identified, analysed and

resolved via remote diagnostics. Such networking with other companies also

enables faster and more efficient processes within those companies and

raises the quality of cooperation in general.

Marketing & sales – more individuality

through digitalisation

However,

the digital revolution does not end when a vehicle leaves the production

line. Mercedes-Benz is also using the opportunities presented by

digitalisation in marketing & sales. Within the scope of Best Customer

Experience, Mercedes-Benz is working with the multi-channel approach that

flexibly interlinks a large number of innovative marketing & sales

formats and digital elements. Major emphasis is being placed on the

digitalisation of all channels – in communication as well as sales

and service. Online stores are enhancing existing sales outlets and making

it possible to order or lease a vehicle at any time.

Greater focus is being placed on digital interaction in the

real world, too. The Mercedes me stores are equipped with a wide array of

digital design elements. Prospects can configure exactly the car they want

easily and conveniently at multi-touch monitors and plasma screens. In

addition, more than half a million people are interacting with

Mercedes-Benz every day via the brand’s global social media platforms

– more than with any other car maker.

The easiest access to the personalised brand world is

offered by the Mercedes me online portal, where Mercedes-Benz is accessible

at any time. The spectrum ranges from electronic appointment booking for

classic customer service, through individual networking with a

customer’s own vehicle to the offer of personally configured

financial services. Customers can also find products that are not

restricted to their own car. This includes mobility services like car2go

and information on lifestyle activities and entertainment

offerings.

Mercedes me was launched one

year ago, enabling customers across Europe to connect with their vehicles

anywhere, anytime. Customers of not-yet networked vehicles will also soon

be able to enjoy the pleasures of conveniently networking their vehicles

– with the Mercedes connect me adapter. A total of 24 car model lines

dating back to 2002 can be retrofitted to enable secure access to vehicle

information. Mercedes-Benz will begin this connect me offensive in early

2016, with successive implementation in European markets where connect me

is also offered.

Mercedes me

– digital access to the personalised world of Mercedes

“Mercedes me always

places the customer front and centre, enabling him or her to access the

brand anywhere, anytime, regardless of whether they need a service, require

entertainment or want remote control of vehicle functions,” said Ola

Källenius, Member of the Board of Management of Daimler AG, responsible for

Marketing & Sales Mercedes-Benz Cars.

Mercedes me innovations include the new Lifestyle

Configurator, which enhances the classic vehicle configurator. The customer

can use it to enter their individual preferences in furnishings, travel

destinations or sporting disciplines and, on the basis of their selections,

is suggested a vehicle that would be the best match for them.

Ola Källenius: “You can use the Lifestyle

Configurator to search for a new Mercedes-Benz in exactly the same way you

would search the internet today for, say, fashion – simply,

interactively and without having to be a technology

buff.”

Dieter Zetsche: “In

Marketing & Sales, digitalisation brings us first and foremost the

opportunity to address our customers’ desires even more individually.

The new Lifestyle Configurator shows us that the digital and real customer

worlds will continue to merge at Mercedes.”

Vehicle communication and data

protection

The rapid development

of communications technology is still opening up completely new

perspectives. Experts assume, for instance, that a 5G mobile communications

network will be up to 100 times faster than LTE. Comprehensive updates to

the car’s software, for instance, can then also be handled online in

just a matter of seconds.

Due to this in

particular, data protection is especially important to the company. Dieter

Zetsche: “The opportunities are enormous; as is our responsibility to

protect our customers’ private lives and to ensure that personal

information does not fall into the hands of third parties. This

responsibility also means our vehicles must be secure against manipulation

from outside. It is therefore our duty and our aim to make our cars as

secure as possible. We are working incredibly hard on

this.”

The digital

transformer – “Concept IAA”

At the Frankfurt International Motor Show, Mercedes-Benz is

showing what digitalisation can mean for the car as a product in real

terms, with the “Concept IAA” (Concept Intelligent Aerodynamic

Automobile). The increase in speed and efficiency through digitalisation is

impressively demonstrated in figures. Design development, which alone would

previously have taken up to two years, was achieved in less than eleven

months.

The Mercedes-Benz Concept IAA is

two cars in one – an aerodynamic world record holder with a

cd figure of 0.19 and a four-door coupé with a fascinating

design. The study, which will be premiered at the IAA in Frankfurt,

automatically switches from Design mode into Aerodynamic mode upwards of 80

km/h, altering its form with a large number of active aerodynamic measures.

Inside, the Concept IAA carries forward the design lines of the S-Class and

S-Class Coupé, offering new, touch-based functionalities and a highly

emotional, digital operating experience. At the same time, the interior

provides a glimpse into the interior of a business sedan of the near

future. Outside, the rear lights are a particular highlight evocative of

the stardust or glow of a jet engine. These lights with their

“stardust effect” will celebrate their premiere in a production

model in early 2016.

The Concept IAA is

also the perfect example of the technologically fundamental changes in the

automotive sector driven by digitalisation. For Mercedes-Benz, a fully

digital process chain from research and development, through production to

sales, logistics and services is far more than science-fiction. Dieter

Zetsche: “What’s definitely clear to me is that this car here

and the outlook for Mercedes Benz have one thing in common – they

both look damn good.”