BMW Engineers Trial Hot New Technologies

MULGRAVE, AUSTRALIA – October 20, 2009: For years, engineers have avoided heat in cars to protect components from overheating.

Now, this goal is being turned on its head as car makers attempt to harness previously wasted energy for practical purposes such as improving fuel consumption and reducing CO2 emissions.

Even a highly efficient engine can only convert about one-third of the energy contained in fuel to actually propel a car. Two-thirds is lost as waste heat via the car’s exhaust and radiator.

Engineers at BMW are currently working on a number of promising projects that make use of heat normally lost. The first idea may banish cold starts forever to reduce emissions. The second approach can convert the heat from a car’s exhaust into electricity, using a similar principle to space probes of the 1960s. The third idea uses waste heat to heat the interior of a car.

“We want cars to warm up as quickly as possible, since higher temperatures mean less friction, less friction means less fuel consumption and, therefore, less CO2,” says Dr Andreas Eder, Head of Heat Management Pre-Development Projects at BMW Group.

No more cold starts

BMW engineers are working all-out on

largely avoiding cold start conditions by fully encapsulating engines.

Improved heat insulation of engines would prevent them from cooling down

quickly and retain as much residual heat as possible for the next

start.

In addition to the air flaps already on some production its production models, a BMW prototype already developed is completely surrounded by fully clad walls and panels using proven materials that are normally used in the car’s underfloor for insulation.

Since the cooling system on new cars is so effective, there is no risk of overheating. Instead, components in the engine compartment which previously had to be cooled at a great effort are now protected better from engine heat.

Thanks to this approach, the engine cools down much more slowly after being switched off and still has a temperature of approximately 40 degrees Celsius after 12 hours. Each degree Celsius above the ambient temperature reduces fuel consumption by 0.2 per cent.

A by product is that materials previously used to dampen noise in the engine compartment are no longer required. Apart from saving fuel, the second customer benefit is a quicker warm up of the interior, which would be appreciated by customers when it is cold outside.

Electric power from waste heat

Another option for reducing CO2

and fuel consumption – by up to two per cent – is a system

which generates electricity from the heat of exhaust gases.

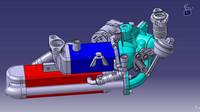

Since presenting the principle of a thermoelectric generator last year, the company is now presenting the next level of development in the form of an integrated component in the exhaust gas recirculation cooler. With the latest development, up to 250 W of energy are produced under typical driving conditions – equal to about half the on-board electricity consumption in a BMW 5 Series.

Between three and eight per cent of the total fuel consumed by modern cars is due to the rising number of electricity-dependent features. To provide this energy without additional consumption, BMW engineers have adapted the idea which first powered space probes in the 1960s.

The thermoelectric generator uses the effect of the temperature gradient in thermoelectric semi-conductor elements generating electrical voltage (the Seebeck Effect). The bigger the difference in temperature, the higher the voltage generated. Exhaust gas temperatures, which are usually between 300 and 900 degrees Celsius, are on the hot side of the generator, and engine coolant is used for the cold side.

Whilst still a prototype, the current solution gives engineers more information on the operating principles as well as obstacles yet to be overcome. This know-how may then be applied in implementing an underfloor solution.

Heating with waste heat

BMW engineers are also working on an

exhaust gas heat exchanger. With petrol engines, it would be very effective

in warming up the drivetrain more quickly to the right temperature,

avoiding friction in, say, the gearbox. Such an exchanger conveys heat, or

thermal energy, from one flow to another, in this case the heat of the

exhaust gas to the oil in the automatic transmission, with additional heat

being pumped in consistently from the start

Diesel engines are now so efficient that the excess heat generated by the engine is usually insufficient to heat the interior of the car alone. It has become quite normal to fit cars with an additional electric heater, which can add up to 1 litre per 100 kilometres. To avoid this extra fuel consumption, hot exhaust emissions may be used by means of a heat exchanger close to the catalytic converter to provide an additional source of heat for the interior. Such a system may avoid the need for electrical heating modules which consume additional fuel.

Given that not every technology is equally sensible for each type of engine, BMW engineers carefully consider which objective can be reached best with which technology and in which context such as size and power of the engine and the car’s main use.