Automotive Materials Life Cycle Assessment Model Released for Use

|

Updated model evaluates the total vehicle life cycle impact of materials, powertrains, fuels and their sources, total energy consumed

SOUTHFIELD, Mich., Aug. 4, 2009; WorldAutoSteel has released a second iteration of the automotive materials parametric Life Cycle Assessment (LCA) model, which allows for broader evaluations of automotive materials, powertrains, fuels and vehicle total energy consumed. Automakers can now more comprehensively evaluate material selection decisions and their effect on greenhouse gas (GHG) emissions, with additional options for materials, emerging powertrains and fuel sources. The Phase 2 model was developed under the leadership of Dr. Roland Geyer of the University of California's Bren School of Environmental Science & Management (UCSB) in Santa Barbara.

The LCA approach assists automakers in evaluating and reducing the total energy consumed and the lifetime GHG emissions of their products. Regulations that consider only the vehicle use phase, or tailpipe emissions, can encourage use of low-density, GHG-intensive materials that provide lighter weight components. However, this may result in increasing GHG emissions during a vehicle's total life cycle.

To investigate the aspects of material selection on automotive LCA GHG emissions, two studies were conducted at UCSB: The Impact of Material Choice in Vehicle Design on Life Cycle Greenhouse Gas Emissions - The Case of High-Strength Steel and Advanced High-Strength Steel Versus Aluminium for Body in White Applications. From this research, a Phase 1 model for material comparisons was developed.

The Phase 2 LCA model is a successor to the Phase 1 model and incorporates many new features and capabilities. Examples include:

-- The original model allowed evaluation of three materials: conventional

steel, advanced high-strength steels and aluminum. The updated model

adds magnesium and several composites to the materials that may now be

evaluated for their emissions from manufacturing through use and

end-of-life;

-- Advanced diesel and fuel cell powertrains are incorporated into the

Phase 2 model;

-- It is now possible to evaluate the impact of bio-fuels and varying

agricultural sources for the production of these fuels; and

-- The model is now capable of producing an analysis of total energy

consumed over a vehicle life cycle, to complement the total GHG

emissions analysis.

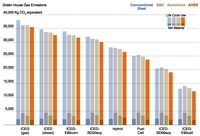

An example of these advanced technologies incorporated within the new model is shown in Figure 1, which compares GHG emissions for steel, aluminum and sheet moulding composite vehicle body structures. Movement along the horizontal axes depicts total life cycle emissions decreasing, which means that material production emissions contribute a greater percentage to the whole. As these technologies are implemented in mainstream vehicle designs, the emissions from material production become more important in the total life cycle. This places greater emphasis on the critical decisions required to choose low GHG-intensive materials such as steel to ensure that total life cycle GHG emissions are reduced.

Figure 1: Life Cycle GHG's, Varying By Materials, Powertrains and Fuel Sources

With reasonable assumptions and inputs for the specific application and manufacturing processes, the material production phase can be a significant percentage of the vehicle's total carbon footprint. In fact, it becomes even more important as the vehicle's footprint is diminished through advanced powertrains and fuel sources. This chart also shows that significant improvements in reducing automotive GHG emissions will not be achieved by material substitution alone. According to the model, the impact of material production and recycling on LCA GHG emissions are relatively small compared to total emissions. Investment in new powertrains and fuels contribute to the greatest emissions reductions.

The Phase 2 model is fully parameterized and developed using a Microsoft Excel spreadsheet. Users can download it free to conduct their own evaluations at the WorldAutoSteel Web site: http://www.worldautosteel.org/Projects/LCA-Study/Phase-2-LCA-Model-available-f or-download.aspx

About Automotive Applications Council

The Automotive Applications Council is a part of AISI's Steel Market Development Institute. The council focuses on advancing the use of steel in the highly competitive automotive market. For more news or information, visit www.autosteel.org.

Automotive Applications Council investors are: -- ArcelorMittal Dofasco -- ArcelorMittal USA -- Nucor Corporation -- Severstal North America Inc. -- United States Steel Corporation About WorldAutoSteel

WorldAutoSteel, the automotive group of the World Steel Association, is comprised of seventeen major global steel producers from around the world.

Our mission is to advance and communicate steel's unique ability to meet the automotive industry's needs and challenges in a sustainable and environmentally responsible way. We are committed to a low carbon future, the principles of which are embedded in our continuous research, manufacturing processes, and ultimately, in our advanced automotive steel products, for the benefit of society and future generations.

To learn more about WorldAutoSteel and its projects, visit www.worldautosteel.org.