DaimlerChrysler Full Of Big Wind (Tunnel That Is)

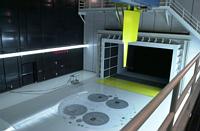

AUBURN HILLS, Mich., June 28 DaimlerChrysler Corporation today opened a new $37.5 million wind tunnel facility that will provide the company with state-of-the-art aerodynamic and acoustic testing capability in the design and engineering of future Chrysler, Jeep® and Dodge vehicles.

"This new facility underscores our company's continued investment in the future and our commitment to bringing high quality, appealing products to our customers," said Dieter Zetsche, Chrysler Group President and Chief Executive Officer.

"The Chrysler, Dodge and Jeep vehicles created with the help of this wind tunnel promise to break new ground in design and performance characteristics, including enhanced fuel efficiency and reduced wind noise."

The 31,000-square-foot Aero-Acoustic Wind Tunnel facility, which will also be used for racing vehicle development, can accommodate vehicles up to 10,000 pounds. The 18-foot turntable permits precise positioning of vehicles during testing. The facility's fans can generate winds in excess of 150 miles per hour to assess aerodynamic drag and wind noise.

"Reducing the air drag is the most efficient way to improve fuel economy, which is a top priority for us," said Dr. Zetsche. "Since the noise levels of powertrains have been greatly reduced, wind noise management is more important than ever. We now have the best tool in the industry to become the benchmark in both areas in the future."

With the use of acoustic materials and other design elements to minimize background sound, the facility is acoustically the quietest wind tunnel currently in use in the automotive industry. This permits the precise analysis of the wind noise characteristics of new vehicle designs. Constant temperature controls allow for precise, repeatable acoustic testing.

The Aero-Acoustic Wind Tunnel is the latest addition to the Scientific Laboratories at the DaimlerChrysler Technology Center, including an expanded powertrain test facility opened in 2000.

"Chrysler has historically been a leader in the study of aerodynamics and the use of wind tunnels in the design and engineering of automobiles," said Bernard Robertson, Senior Vice President, Engineering Technologies and Regulatory Affairs. "This new facility will ensure that we maintain that leadership well into the future."

The new aerodynamic and acoustic test facility is located on the south side of the technology center, with easy access to the Design and Engineering centers and vehicle fabrication shops.

"The wind tunnel is the cornerstone of our lab and test facilities," said Donald Goodwin, Vice President and head of the Scientific Laboratories and Proving Grounds for Chrysler Group. "It is a critical link in the design and development of new vehicles. Our proximity to the rest of the vehicle design and engineering functions will reduce the time and cost of bringing a new vehicle to market. For example, we can provide test results on new clay models to the Design Center on an overnight basis."

The Aero-Acoustic Wind Tunnel is designed to accomplish three functions in the vehicle development process:

Enhance fuel efficiency and performance of Chrysler, Dodge and Jeep vehicles through improved aerodynamic design Minimize wind noise levels Validate performance of exterior vehicle components through whole- vehicle testing in operating speed ranges. "In this tunnel, we can produce wind speeds of more than 150 miles per hour," said Mark Gleason, Supervisor of Aerodynamic Wind Tunnels. "That enables us to test the aerodynamic, acoustic and functional performance of even the fastest vehicles for the American and European markets. And, we will also be a major factor in the development of racing vehicles supported by DaimlerChrysler.

"In addition, the wind tunnel is large enough to accommodate testing of the full range of vehicles," Gleason said. "We can test everything from a Dodge SRT-4 to the largest Ram pickup without concern that there will be significant distortions in the air flow in the tunnel. That gives us a real advantage over smaller wind tunnels."

Gleason will head up a team of seven aerodynamic and acoustic engineers who will conduct operations at the new facility, which is already fully booked through the end of 2002.

DaimlerChrysler designers and engineers will continue to use the company's three-eighths model wind tunnel and computational fluid dynamics (CFD) as complementary tools to the new full-scale facility.

"We have a magnificent new facility here, with the best combination of aerodynamic and acoustic characteristics in the world," said Jean Mallebay- Vacqueur, Director, Environmental Laboratories for Chrysler Group. "With the experience and skill of the automotive 'aerodynamicists' and 'aeroacousticians' on our staff, we will be able to capitalize on the capabilities of this new facility to the fullest."

The three-year wind tunnel construction project was completed on budget and ahead of schedule.