Want Indoor Racing? - The New FLRacing Kart; Smart, Quick, Fun, And All Green, All The Time

|

FLRacing Karts recently introduced their electric kart, noticing the rise in demand for electric karts which has increased as the concept of indoor karting has become more popular. While a look at Indoor Kart Tracks.Com shows that there are 94 indoor kart tracks in the U.S. this is a small number in comparison to the nearly 500 tracks that are in Europe and the almost 1500 electric kart tracks Worldwide.

|

WHY AN FLRACING ELECTRIC KART?

Zero Emissions = Clean Air and Lower Operating Costs:

Gas powered indoor karting facilities must bear the initial cost of an expensive air handling system that attempts to eliminate noxious and deadly gasses emitted by internal combustion engines. Beyond the initial costs, there are continuous increased operational expenses. The very system designed to refresh and replenish the inside air, is in fact removing seasonal climate controls. Track operators must balance these opposing efforts and the results are that the air in these facilities is still contaminated! Electric karts emit no air pollution whatsoever. City codes and inspectors meet the approval of electric go-kart tracks or facilities, however, with gas karts, they have previously denied or not passed the rigorous standards of city codes.

Whisper Quiet Operation = Longer Operating Hours:

|

When you first enter a conventional karting facility, the roar of the karts fills you with excitement – for about five minutes. After that, the loud, incessant droning is more likely to give you a headache. Customers there to enjoy the facility are driven away. There is no way to bring the noise level of gas engine karts down to an acceptable level. Electric karts on the other hand create almost no noise, except a pleasant high-pitched whine like an F-1 racecar. This translates to longer operating hours and fewer complaints from your crew, customers and neighbors.

Electrical Power = Reduced

Costs and Elimination of Hazards:

The operation of internal combustion karts requires fuels such as gasoline, propane, or methanol. The fuel must be purchased, delivered, stored, dispensed, and handled on-site. In many instances, local or state authorities will not allow this indoors. In addition, oils and lubricants must be properly handled and legally disposed. Electric karts use no gas or oil. This means no fumes, no spills, no air pollution, and none of the hazards or related costs associated with toxic liquids. Electric karts need no "re-fueling", translating to fewer man-hours and fewer hazards. Electric kart batteries are UL rated and fully recyclable. The next generation in FLRacing Karts is already in progress, testing of Lithium batteries and a Patent on a “Quick Change Solution” in Lithium will keep the track owner from having to purchase extra karts to charge. The “Quick Change Solution” allows the kart to pull in when a re-charge is needed and to have a plug in Lithium battery pack pulled out and a new one put in within 20 seconds.

Fewer Moving Parts = Lower Maintenance Costs:

|

Electric motors have lower maintenance costs than gasoline engines. This translates into savings for the track operator, as fewer repairs are needed. Motors need no maintenance and run for years before needing a simple brush and bearing replacement. Combined with superior chassis, design, and strength, FLRacing karts will give years of service. The use of dry lead acid batteries means there is no need to deal with messy, toxic acid.. Extremely long lasting, and the available power stays constant to provide thousands of exciting races. New and exciting advances in the Lithium battery which is now being tested in FLRacing Karts are sure to make for quicker charges and longer kart runs.

Low End Torque = Faster Acceleration:

Electric karts cannot only match gas karts for top speed on straight-a-ways, their low-end power and quickness provide head-snapping acceleration throughout the entire range of speeds. Instead of a "live solid axle", electric karts have unique, custom-built differential that amplifies the kart’s turning response, improves handling, engine performance and battery life. The resulting performance makes for a truly exhilarating racing experience.

Remote controlled, Safer, Saner and more Fun!:

Our electric karts feature state-of-the-art radio controlled emergency shut-off and pit speed reduction. The radio control allows track personnel to control the track speeds before, during, and after a race. The pit lane speed allows the customers to enter and exit the pit lane grid safely. The system can also be used to penalize individual drivers who have made intentional infractions of track rules, by remotely cutting their kart’s power in half. Speeds are fully adjustable to suit your track design.

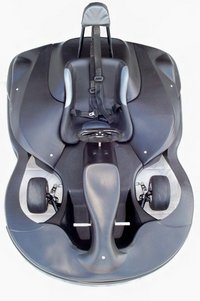

CHASSIS

Tubular

frame utilizing square, rectangular and round DOM tubing provides

exceptional strength and durability

Frame is assembled in a clamp down

jig for increased accuracy and MIG welded for durability

Powdered

coated for a strong scratch resistant finish

BODY

Body

panels are vacuum formed high density polyethylene to reduce damage from

impacts

Panels are easily removed for inspection or maintenance with ¼

turn fasteners

Standard XL seat accommodates most drivers

Powered

seat and pedals adjust with the push of a button

BUMPERS

Impact resistance high density polyethylene bumpers front and rear

are reversible for longer life

Additional shock absorption is provided

by rubber “D” section extrusions at the front, rear and

sides

BRAKES

Hydraulic system with master cylinder and

rear wheel calipers

Fully adjustable pads provide more control when

adjusting the brake disk location

Stainless steel braided brake lines

for durability

DRIVELINE

Steel primary and secondary

sprockets

Number 40 roller-chain

Chain tensioning easy and simple

to do

REAR AXLE

Dual 30mm axle shafts

Dual supports

for each axle reduce deflection

Aluminum differential with steel bevel

gearing

BATTERIES

Maintenance free 12 volt 50 amp/hr

Spiral wound cells with gas recombination technology

Sealed valve

regulated battery means no leaks to worry about

MOTOR

SEP (separately exited) DC motor provides instant power

Powered by 48

Volt system

CONTROLLER

Programmable

Reverse

direction with the push of a button

Potentiometer provides smooth

control of speed

500 amp rated

OTHER PHYSICAL INFORMATION

Four point seat belts system

Tire sizes are 10 x

4.50-5 front and 11 x 7.10-5 rear

Overall width and length

approximately 58” x 81”

Inside turning radius approximately

8.5 feet