Legend in Progress

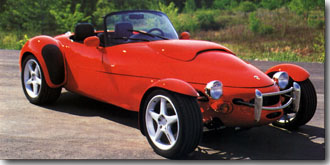

Thirty-something years ago Carroll Shelby created a performance legend. Now Panoz is in the catbird seat.

Legend in Progress

Thirty-something years ago Carroll Shelby created a performance legend. Now Panoz is in the catbird seat.

The Dream Materializes

Although the name Panoz seems to have suddenly appeared overnight in today's public automotive consciousness, the fact is that it has taken Danny eight careful years to build his dream. And he admits that it has taken even longer to figure out how to avoid the pitfalls that caused others to crash or flame out.

Although the name Panoz seems to have suddenly appeared overnight in today's public automotive consciousness, the fact is that it has taken Danny eight careful years to build his dream. And he admits that it has taken even longer to figure out how to avoid the pitfalls that caused others to crash or flame out. Financial Reality

Panoz Methodology

The Braselton Bullet

As we walk through the factory, Panoz points down the assembly line. "Georgia and the Carolinas are centers of American automotive enthusiasm," he explains. "Guys down here grow up in a car culture something like California had in the '50s and '60's Shelby proved that you need that to build great cars." Unfortunately it's an environment that no longer exists on the West Coast. It's no secret that BMW, Mercedes and Nissan put their new factories in the Southeast partly because the labor pool there loves and understands automobiles. Fifty years of NASCAR racing in the area have developed an enthusiastic car culture that provides thousands of jobs in the local racing industry. Panoz notes with pride that several of his veteran assembly technicians are ex-NASCAR racers. "These boys live and breathe cars; it's what helps us build the best - nobody is going to let something go down our line that isn't right." It's much the same spirit that permeated Shelby's operation in the '60s, only those were much simpler times - and Shelby didn't really build cars; he ordered completely finished components from AC's plant in Thames-Ditton, England or the Ford assembly plant in San Jose, California and put the finishing touches on them in his shop near LAX in Los Angeles. Danny Panoz' operation in Braselton is already far beyond what Shelby ever had or envisioned.

As we walk through the factory, Panoz points down the assembly line. "Georgia and the Carolinas are centers of American automotive enthusiasm," he explains. "Guys down here grow up in a car culture something like California had in the '50s and '60's Shelby proved that you need that to build great cars." Unfortunately it's an environment that no longer exists on the West Coast. It's no secret that BMW, Mercedes and Nissan put their new factories in the Southeast partly because the labor pool there loves and understands automobiles. Fifty years of NASCAR racing in the area have developed an enthusiastic car culture that provides thousands of jobs in the local racing industry. Panoz notes with pride that several of his veteran assembly technicians are ex-NASCAR racers. "These boys live and breathe cars; it's what helps us build the best - nobody is going to let something go down our line that isn't right." It's much the same spirit that permeated Shelby's operation in the '60s, only those were much simpler times - and Shelby didn't really build cars; he ordered completely finished components from AC's plant in Thames-Ditton, England or the Ford assembly plant in San Jose, California and put the finishing touches on them in his shop near LAX in Los Angeles. Danny Panoz' operation in Braselton is already far beyond what Shelby ever had or envisioned. Historical Perspective

Panoz Versus Prowler

Dogged Adherence To The God

International Vision

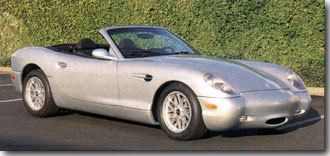

During this period, engineer John Leveritt and fabricator Mike Crawford had taken one of their 1/5 scale Esperante models and converted its lines to a full GT racer. Reynard offered to test the scale model's aerodynamics in his wind tunnel in England. The test results were so positive that Reynard suggested using the production car's general form as the basis for a new GT racing car that could compete against Porsche and McLaren at Le Mans. "Sure," said Danny, "but it's gotta' be front engined and it has to use a stock Ford pushrod V8 - just like we use in our Roadster!" At that time, the Panoz AIV Roadster was using Ford's 351

"Cleveland" small block. When Reynard returned several weeks later with the redesigned windtunnel model and the comparative aero figures projected against the Porsche and McLaren coupes, the Esperante project for both road and track was given the green light. It was a huge commitment for the Panoz family. There was only one reservation...time. Activities were so compressed at the tiny Georgia facility that it was decided that Danny would continue to concentrate on production cars, while the elder Panoz would concentrate on motorsports. At the time, Donald Panoz wasn't a "car guy" in any sense of the word and in fact had never even been to an auto race in his life! He didn't know an A-arm from a drive shaft but he liked Reynard's approach and the professionalism of his staff. Don had also read up on Shelby's Le Mans history and knew if his son ever expected to have any true credibility as a legitimate manufacturer in the world of sports cars he'd need some racing exposure.

During this period, engineer John Leveritt and fabricator Mike Crawford had taken one of their 1/5 scale Esperante models and converted its lines to a full GT racer. Reynard offered to test the scale model's aerodynamics in his wind tunnel in England. The test results were so positive that Reynard suggested using the production car's general form as the basis for a new GT racing car that could compete against Porsche and McLaren at Le Mans. "Sure," said Danny, "but it's gotta' be front engined and it has to use a stock Ford pushrod V8 - just like we use in our Roadster!" At that time, the Panoz AIV Roadster was using Ford's 351

"Cleveland" small block. When Reynard returned several weeks later with the redesigned windtunnel model and the comparative aero figures projected against the Porsche and McLaren coupes, the Esperante project for both road and track was given the green light. It was a huge commitment for the Panoz family. There was only one reservation...time. Activities were so compressed at the tiny Georgia facility that it was decided that Danny would continue to concentrate on production cars, while the elder Panoz would concentrate on motorsports. At the time, Donald Panoz wasn't a "car guy" in any sense of the word and in fact had never even been to an auto race in his life! He didn't know an A-arm from a drive shaft but he liked Reynard's approach and the professionalism of his staff. Don had also read up on Shelby's Le Mans history and knew if his son ever expected to have any true credibility as a legitimate manufacturer in the world of sports cars he'd need some racing exposure. But Wait There's More...

|

| |||||||||||

Copyright © 1996, 1997, 1998 The Auto Channel.

Send questions, comments, and suggestions to

Editor-in-Chief@theautochannel.com