Chrysler Group LLC and U. S. Environmental Protection Agency Announce new Research Project for Hydraulic Hybrid Powertrain

SEE ALSO: Big Oil Benefits From Divide and Conquer

AUBURN HILLS, Mich., Jan. 19, 2011; Chrysler Group LLC and the U. S. Environmental Protection Agency (EPA)

today announced a partnership to determine the possibility of adapting a

hydraulic hybrid system for large passenger cars and light-duty

vehicles. The announcement was made at the EPA laboratories in Ann Arbor, Mich., following a meeting with Sergio Marchionne, Chrysler Group CEO, and Lisa P. Jackson, Agency Administrator for the

EPA. "In addition to creating the jobs of the future, clean energy benefits

the U.S. economy by ultimately making energy costs more affordable for

consumers, especially if their dollars stay in America,"

Marchionne said. "Hydraulic hybrid vehicle technology is one more promising

path worth pursuing in the effort to reduce our carbon footprint, and we

are excited to partner with the EPA to push forward on this track." "Hydraulic hybrid vehicles represent the cutting edge of fuel-efficiency

technology and are one of many approaches we're taking to save money for

drivers, clean up the air we breathe and cut the greenhouse gases that

jeopardize our health and prosperity," said EPA Administrator Lisa P. Jackson. "The EPA and Chrysler are working

together to explore the possibilities for making this technology affordable

and accessible to drivers everywhere. This partnership is further proof

that we can preserve our climate, protect our health and strengthen our

economy all at the same time." The hydraulic hybrid system, developed by the EPA's lab in Ann Arbor, is well known and currently used in

industrial applications, including large delivery trucks and refuse trucks

across the country. The technology has shown substantial increases in fuel

economy when compared with traditional powertrains in the same type of

vehicles. Working together, both parties hope to reduce the size and

complexity of the hybrid system and produce a technology that is sensitive

to the needs of drivers for smooth and quiet operation. The research project will focus on adapting the hydraulic hybrid system

to a Chrysler Town & Country minivan equipped with a 2.4-liter, inline

four-cylinder gasoline engine. Components of the hydraulic hybrid system

include a 117 cc engine pump, a 45 cc drive electric motor and a two-speed

automatic transmission. Fluid for the system will be stored in a

14.4-gallon high pressure accumulator. The system produces power with engine torque driving a hydraulic pump

that charges the high pressure accumulator of up to 5,000 p.s.i. The

high-pressure accumulator delivers the pressure energy to the axle

hydraulic motor, giving the vehicle power to drive the wheels. The gas

engine will remain off if the accumulator charge is sufficient to drive the

motor. "In this hydraulic hybrid project, the Chrysler Group and EPA will

evaluate and, hopefully, validate fuel-efficiency gains and greenhouse gas

reductions," Marchionne said. "One of the aims of Chrysler Group's

integration efforts will be to meet driver expectations for smooth and

quiet operation, so that Americans will want to buy and will enjoy driving

vehicles with this technology." The Chrysler Group has actively adopted fuel-saving technologies

including cylinder deactivation on V-8 engines, a new MultiAir system that

is being introduced on the Fiat 500 today and will introduce an eight-speed

transmission in the 2011 Chrysler 300 that will be introduced later this

year. Chrysler Group also will introduce 150 Ram 1500 trucks with a plug-in

hybrid system in the coming months as part of a project with the U. S.

Department of Transportation. Hybrid vehicles use two sources of power to drive the wheels. In a hydraulic hybrid vehicle (HHV) a regular internal combustion engine and a hydraulic motor are used to power the wheels. EPA and their partners have implemented both series and parallel HHV technology in multiple vehicles. To see some of these HHVs in action visit Demonstration Vehicles. Series HHV technology significantly increases fuel economy and reduces emissions at very low additional cost. Hydraulic technology is also incredibly powerful and efficient for operations that require huge amounts of power. That means that HHVs can not only perform as well as conventional vehicles, but can also be designed to provide superior performance acceleration and quiet engine off operations. Hydraulic hybrid technology is also notable for its versatility. Hydraulic hybrid technology can be applied to military vehicles, buses, urban delivery trucks, refuse haulers, as well as sports utility vehicles and family sedans. Without the weight of a conventional transmission coupled with more efficient performance in stop-and-go traffic, HHVs make ideal urban vehicles. Hydraulic hybrid technology can also be used in smaller vehicles. This technology has even been demonstrated in a bicycle. To learn more visit our Hydraulic Hybrid Bike Page. The bottom line is that hydraulic hybrid technology is simple, clean, efficient and cost effective. Three key design features help full series HHVs achieve maximum fuel efficiency: EPA is on the cutting edge of research and development of hydraulic hybrid technology. EPA has achieved major breakthroughs in the design and operation of pump/motors and accumulators by making them smaller, lighter, and more efficient. These breakthroughs led to the development of applications for both large commercial and smaller consumer vehicles. The unique hybrid drivetrain design has also been combined with EPA's work on advanced, cleaner, and more efficient engines. To commercialize these breakthroughs EPA has cooperative research and development agreements with several private sector partners. Visit our Demonstration Vehicles page to learn more about

vehicles that EPA has developed in cooperation with its industry partners. For additional information

on the partnerships visit our Partnerships page. To find

out about EPA's latest advances visit the Newsroom page. EPA Hydraulic Hybrid Research

What Are HHVs?

Hydraulic hybrid systems consist of two key components: high pressure hydraulic fluid vessels called accumulators, and hydraulic drive pump/motors. The accumulators are used to store pressurized fluid. Acting as a motor, the hydraulic drive uses the pressurized fluid to rotate the wheels. Acting as a pump, the hydraulic drive is used to re-pressurize hydraulic fluid by using the vehicle’s momentum, thereby converting kinetic energy into potential energy. This process of converting kinetic energy from momentum and storing it is called regenerative braking.

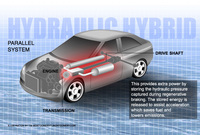

There are two types of HHVs: parallel and series. In parallel HHVs both the engine and the hydraulic drive system are mechanically coupled to the wheels. The hydraulic pump-motor is then integrated into the driveshaft or differential. To learn more visit: How Parallel HHVs Work.

Series HHVs rely entirely on hydraulic pressure to drive the wheels, which means the engine does not directly provide mechanical power to the wheels. In a series HHV configuration an engine is attached to a hydraulic engine pump to provide additional fluid pressure to the drive pump/motor when needed. To learn more visit the page on How Series HHVs Work. Benefits of HHVs

Why Are HHVs So Efficient?

EPA's Role