Art Vatsky, P.E. Explains Coates Spherical Rotary Valve Technology

WALL TOWNSHIP, N.J.--Coates International, Ltd. (OTCBB: COTE) announced that Art Vatsky, a well-known professional engineer and CEO of Future Fuels Technology, has provided a clear explanation of the company's technology. That independent report is as follows:

"An Elegant Solution for Today’s Internal Combustion Engine Valves

Improved Engine Breathing, Reduced Internal Friction, Lower Production Cost"

George G. Coates, CEO of Coates International, Ltd. has devoted a good part of his career to developing and perfecting a spherical rotary valve to be used to replace poppet valves in internal combustion piston engines.

After visiting Coates International last December and January, and witnessing operation of generator set and motorcycle engines, reviewing components and discussing theory, Art Vatsky, P.E., mechanical engineer and principal at Future Fuels Consulting, Teaneck, NJ reported: “With more than a billion engines in use today, the Coates SRV is a long overdue and important advance.” It is possible to make the significance clear by defining the terms of the Spherical Rotary Valve.

- Valve - acts as a door – it can be open or closed. It allows flow when open or halts flow when closed. In today’s engines, the “doors” are poppet valves, which control air into and exhaust gas out of engine combustion chambers. They require close tolerances, special materials, and many small parts. They move in and out – reciprocal motion – at very high speeds that cause wear, vibration and noise. They consume power and are a constraint on modern engine design.

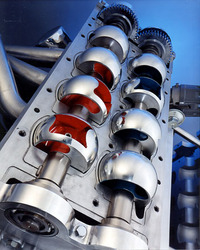

- Rotary - The Coates valve is like a revolving door – with fewer parts, continuous motion, and near silent operation. The Coates rotary valves successfully replace the current complex poppet valve train, providing a clear flow area when open and an effective seal when closed.

- Spherical – refers to the sealing surface of the Coates rotary valve. The Coates rotary valve looks like a section of a globe. The spherical surface allows the seals to closely conform to the valve at all speeds and temperatures.

By successfully replacing reciprocating motion by rotation, Mr. Coates has achieved an elegant solution to a problem – the limitations of poppet valves – most engineers have chosen to accept rather than solve.” The CSRV allows engines to operate with lower internal friction and vibration, with better breathing capability, with higher compression ratios, and at higher rotating speeds. In other words, employing CSRV allows for smaller, faster, higher performing, more efficient engines just when industry is desperately seeking such results. Further, the Coates SRV is scalable to all size piston engines and adaptable to today’s existing engine designs. Its components simply replace the poppet valve and valve train portion of an engine, leaving other major components unchanged. There is no need to retool entire engine factories to use the CSRV system. Finally, the CSRV system is compatible with all the conventional and alternate fuels under development including biofuels, natural gas and hydrogen.

The world market for new engines is very large for industrial, automotive, construction equipment, and a myriad of other applications. All these applications face the need for higher efficiency, lower emissions and costs. In the US there are nearly 240 million registered road vehicles according to the US Department of Transportation.

World diesel engine sales are currently estimated at $25 million a year. Overall, more than 150 million engines are being manufactured each year. Coates SRV technology is ready just when the world engine market needs it."