15th Tech Crawl, On Site Report: The Auto Channel Looks Into

Auto Technology's Future

By Thom Cannell and Steve Purdy

Senior Editors

The Auto Channel

Michigan Bureau

Annually the Detroit press corps is invited to a daylong deep

dive into a variety of technologies offered by companies represented by a

very active PR firm, AutoCom, which is now in its 20th year. This 15th Tech

Crawl, like the others, attracted a flock of reporters from technical

magazines, newspapers, blogs, popular magazines, and dot-coms like The Auto

Channel. Steve Purdy and Thom Cannell of TACh’s Michigan Bureau again

share their views on technologies ready for prime automotive time,

including some interesting details on how air bags are tested, a timely

topic in the news right now.

|

Client presentations began with a

highly esoteric, “inside baseball” corporation - ARaymond who

makes all manner of fasteners and quick-connect systems - 100 billion of

them each year for connecting a fuel injector to a fuel rail or simply

pushing a plastic pin into a hole to keep your dashboard or door panel

attached. ARaymond, headquartered in the French Alps, is celebrating its

150th anniversary and the company is now run by the fifth generation of the

founding family. CEO Antoine Raymond was in town doing a tour of all their

facilities with his 82-year-old retired father from whom he took the reins

almost 15 years ago. Celebrating a major expansion of their facility in

nearby Rochester Hills, the ribbon-cutting ceremony featured a ribbon with

a connector in the center so no scissors were needed.

|

Another

AutoCom client, Foretech, makes a variety of niche liquid products.

They’re the Casite Motor Honey, BarsLeak, and Rislone people. What

you probably don’t know about are their singular products like a

coating that’s applied to virtually every pickup rear axle as a

corrosion prevention, or what’s called lapping compound, a gritty

substance that mates differential parts, grinding them as a unit until they

match surfaces to perfection.

Are you racy enough to recall

Cosworth, the racing and powertrain company? They’re now a division

of the huge German MAHLE group and since 2005 has worked on advanced

sensors, turbulent jet ignition (a process relating to perfect internal

combustion in each engine cylinder), engine controls, and test systems.

They brought two exciting ideas, both ready for introduction.

German MAHLE group The

first is a method of using GPS data to help range-extended vehicles

maximize fuel economy while preserving battery charge - think Volt or

Hyundai’s PHEV. If your engine computer

were hooked to the GPS it would know that a hill is approaching so it could

run the internal combustion range extender (and they have a purpose

developed Rex about the footprint of a legal pad) at its most efficient to

recharge the battery on the downhill run and use more electrons on the

uphill. It would also know when you’re in a residential area so

you’d never startle the neighbors with noise. For cities - Amsterdam,

London, Paris - which are rapidly demanding electric-only vehicles,

imposing stiff taxes on combustion engines in the city or banning them, you

could predict driving into a city and preserve battery charge, never paying

the fees. Oh, the tech also delivers fuel economy for fleets like UPS and

others exploring alternative fuel trucks and delivery vehicles.

|

MAHLE’s second offering, an almost-available product, is designed for

your local independent mechanic, a guy, girl, or family who has to buy

expensive machines to diagnose the ills in your new vehicle by

communicating with the multiple microprocessors that govern everything from

interior lights to spark at the plugs. Tech Pro, in Beta testing now, is a

compact diagnostic data set that runs on a laptop, desktop, or even

inexpensive tablet computer. Once hooked into the car’s data stream

(every device, manufacturer or aftermarket, hooks in the same way) the

device reads an unbelievable amount of test data. You can flash the

flashers, squirt water out of the window washers, pump the brakes, diagnose

misfires; the list goes on, and on, and on...

Cost to your

independent shop (some dealerships will use Tech Pro instead of buying the

very expensive manufacturer’s test equipment) is $1200 a year and

Cosworth/MAHLE thinks payback will be in three months. Current data sets

cover 2007 Ford, GM, FCA/Chrysler products, soon the Asians, then European

models. Later the product will reach backward to include older models. Tech

Pro uses OEM data, which Cosworth licenses, so it is not a derived data

set. It’s the real thing.

Hella, a company best known for

lighting systems, did little to illuminate our group. Bad pun. They did

spend a great deal of time educating us on how radar systems are used to

help drivers. Things like blind spot warning, assistance in changing lanes,

detecting traffic crossing behind you (including pedestrians and

bicyclists). They also described newer systems, ones designed to let you

know you shouldn’t open your passenger or driver door and crash a

motorcyclist of bicyclist, warnings for tractor-trailer drivers designed to

detect the fools who hide out in blind spots.

|

What we learned was

that 24GHz radar systems (gigahertz, a measure of the radar frequency) are

cheaper because they are currently mass-produced. Newer 77GHz radars

deliver far better resolution of detected objects, but at currently much

higher price. Globally, most manufacturers use 24Ghz radars. However, the

77 GHz band is free for industrial, scientific, and medical use with little

governmental regulations. Also, compared to camera systems, radar cannot

detect contrast and shapes. Camera systems, even infrared systems, are poor

at fog, snow, sleet and other bad weather. Combining radars, even with

camera systems, provides manufacturers with their idea of the best

technology for their buyers.

|

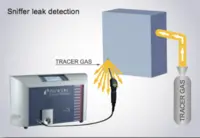

The final presentation came from

INFICON, a small Swiss company that makes leak detection equipment.

Briefly, just about every fuel system part needs to be tested because of

modern fuel injected engines. When Thom Cannell worked at Oldsmobile, his

job was to watch for bubbles as fuel tanks were dunked in water and

pressurized. Today, filling parts with helium and using INFICON’s

sniffers to detect the leaking gas can detect tiny leaks that aren’t

large enough to form bubbles. Currently, air conditioning systems are leak

tested, engines are leak tested, and modern 8-9 speed transmissions are

tested several times to insure quality. Just about every system on the car,

along with many individual components, need to be leak tested and INFICON

does it.

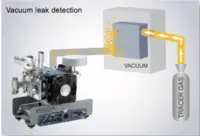

That led to a discussion of air bag testing, a very hot

topic in the news right now.

Air bags are inflated by what are,

essentially, powerful firecrackers. Way sophisticated, but nonetheless,

explosive devices. The problem, described modestly well in nightly news, is

that if water vapor, even a few molecules a day, creep into an air bag

inflator over time the fuel system, the “explosive”, degrades

and burns too rapidly. It goes bang instead of whoosh, producing too much

energy too quickly and sometimes blowing apart that metal hockey puck like

a hand grenade.

One air bag igniter manufacturer, AUTOLIV, is an

INFICON client. They laser weld two steel “hockey pucks”

together to form the igniter body. Inside are measured amounts of hydrogen.

For quality control even those few milligrams of gas contribute to overall

weight, and weighing each igniter prevents a damaged, leaked out unit from

passing a leak test.

A machine puts each igniter into a body, pulls

a vacuum, and if any hydrogen leaks out the unit is failed. Also, a bottle

of hydrogen with a calibrated leak is used to calibrate the unit

periodically. IFICON says that about 300 million igniters are made each

year and about 600 million tests are performed.

After the formal

presentations another AutoCom client, Italian company Alcantara, was

outside with a new Lincoln MKX Black Label showing off their unique product

- an environmentally-friendly, fully sustainable, carbon neutral synthetic

suede used in a variety of auto interior applications – headliners,

seats, door panels, etc. That material is also very big in fashion,

interior design and other applications and it is pretty cool stuff. It

comes from petroleum so no cows had to die to make it – though I

guess we could say some dinosaurs may have been in the mix. The cost is

about the same as leather currently.

We always find it fascinating

to explore and try to understand these high-tech elements that go into

making our cars. AutoCom’s clients, tier-one and tier-two auto

suppliers, ride this wave of blindingly fast scientific development and

fortunately share it all with us periodically, so we can share it with you.

Stay tuned. We’ll be covering more.

© Cannell & Associates and Shunpiker Productions